|

Hoso Metal Co., Ltd

|

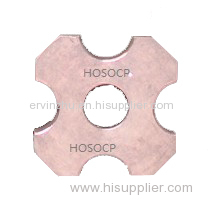

tungsten copper Conductive mouth

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Plastic injection molding is a kind of plastic products manufacturing process.

Plastic injection molding is a kind of plastic products manufacturing process. Liquid plastic through hot runner transports into mould. Many plastic need exact processing temperature, because if temperature is too high, material is possible to damage; if temperature cools too quick, plastic harden and it can't flow into mould according to expected vision. Therefore, thermal transmission is very important in hot runner nozzle nozzle.

If we need keep plastic under appropriated temperature, we need to add heating coil to heat nozzle from outside. We don't need to use heating equipment heating inside of nozzle. Hot runner nozzle must transfer heat to plastic, so thermal conductivity of materials plays an important role. General metal is lack of thermal conductivity, such as copper. Although thermal conductivity of copper is very high, it can't tolerate abrasive plastic.

We research and develop a generation of material of hot runner nozzle nozzle, which has high thermal conductivity and is up to 140W/mK. What's more, a generation of material of hot runner nozzle nozzle has excellent thermal conductivity, corrosion resistance. If we proceed heat treatment after processing, it will be higher corrosion resistance.